VBN Components Products

VBN Components Vibenite High Hardness, High Wear Resistance Alloy Powder for Metal 3D Printers

The Vibenite series is a High-Hardness, High-Wear-Resistant Alloy Powder Material that enables modeling with a Metal 3D printer.

There are five types of powder steel, and you can select the type of powder that has higher hardness, high-temperature hardness, corrosion resistance, and toughness according to your application.The Vibenite series has a high carbide content, but like conventional cemented carbide processes,No need to mix, dry, press or sinter. Modeling with a metal 3D printer is possible.

Custom modeling is also possible with the metal 3DP equipment owned by VBN Components (max build space: about 200 x 200 x 380 mm).

Applications include power skiving cutters, large gear cutting hobs, pressure die casting tools, plastic and metal forming tools, cutting knives and wear protection tools.

The Vibenite series is a High-Hardness, High-Wear-Resistant Alloy Powder Material that enables modeling with a Metal 3D printer.

There are five types of powder steel, and you can select the type of powder that has higher hardness, high-temperature hardness, corrosion resistance, and toughness according to your application.The Vibenite series has a high carbide content, but like conventional cemented carbide processes,No need to mix, dry, press or sinter. Modeling with a metal 3D printer is possible.

Custom modeling is also possible with the metal 3DP equipment owned by VBN Components (max build space: about 200 x 200 x 380 mm).

Applications include power skiving cutters, large gear cutting hobs, pressure die casting tools, plastic and metal forming tools, cutting knives and wear protection tools.

Vibenite High Hardness, High Wear Resistance Alloy Powder for Metal 3D Printers

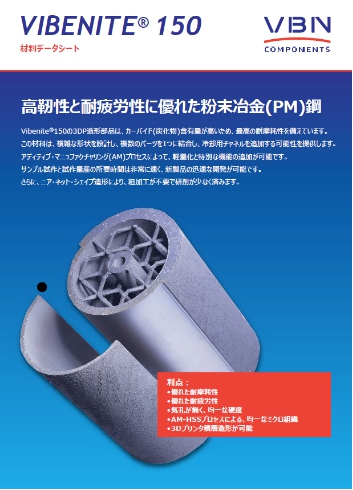

Vibenite ®150

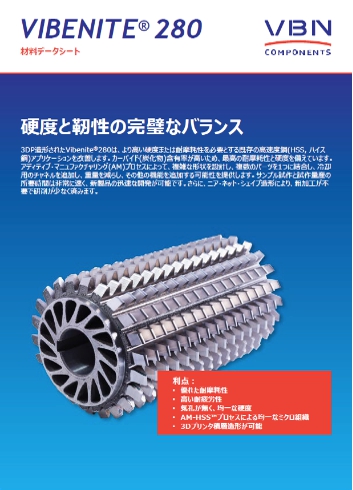

Vibenite ®150 Vibenite ®280

Vibenite ®280 Vibenite ®290

Vibenite ®290 Vibenite ®350

Vibenite ®350 Vibenite ®480

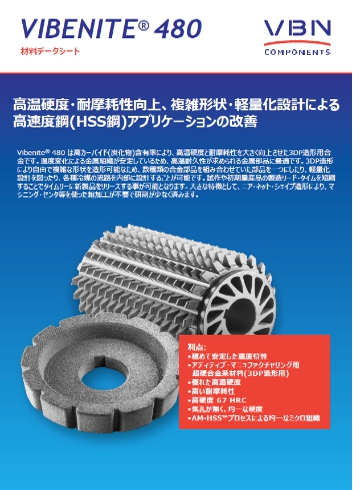

Vibenite ®480

- Material

-

Vibenite Series Line up

・Vibenite ®150:Wear Resistant PM Steel with High Toughness and High Fatigue Resistance

・Vibenite ®280:PM Steel with Hardness and toughness perfectly balanced HSS applications

・Vibenite ®290:The world's hardest steel, Higher Hot Hardness or Higher Abrasion Resistance

・Vibenite ®350:Martensitic Stainless Steel with Supreme Wear Resistance

・Vibenite ®480:Patented Cobalt-Chromium (CoCr) based alloy with very high levels of tungsten (W) and carbon (C)

- Applications

-

・Vibenite ®150:Applications with demands on both wear resistance and toughness, plastic materials processing tools, wear parts, functional prototypes, parts difficult to machine,cold working tools, tool holders, molds, blasting nozzles, knives, etc.

・Vibenite ®280:Components, tools, and materials that wear out too fast benefit from being replaced by Vibenite® 280.

Auto-motive, food, blasting, oil and gas, mould, and cutting applications (coated or un-coated).

Examples; erosion protection, abrasive wear parts, gear hobs, broaches, shaper cutters, power skiving cutters, drills and taps, hot working tools, etc

・Vibenite ®290:The unique composition of Vibenite® 290 results in a ma-terial perfect for metal-cutting tool applications such as gear-cutting hobs, power-skiving cutters, shaper cutters and dry-cutting applications. The material is also very suitable in abrasive and/or ero-sive wear applications.

This new alloy gives users a unique opportunity to choose the best performance for the application without having to resort to difficult machining.

・Vibenite ®350:The alloy is very suitable for high-wear applications that also need stainless properties, e.g. knives in the food processing industry, plastic processing tools (extrusion and injection tool parts, segments for segment screws), pumps and pump houses, plain bearings (bushings) and valve rings.

Customers have reported ten (10) times longer lifetime of Vibenite® tools compared with stan-dard tools.

・Vibenite ®480:Typical applications are tools or components that require excellent wear resistance and hot hardness.

Vibenite® 480 is very suitable in applications where traditional cemented carbides are too brittle and the heat resistance of PM-HSS is too low.

Examples include: metal cutting tools (e.g. gear hobs, power-skiving cutters and shaper cutters);dry cutting applications; applications requiring high resistance to abrasion/erosion; applications where there is extreme heat and wear; and sliding surfaces.

Despite the extremely high level of carbides in the material, it still resists corro-sion (see below). Thus, it can also be used in applications where corrosion is unavoidable(e.g. woodworking tools, textile and paper knives and the food industry).

- PDFCatalog

-

LOGIN※To view the detailed catalog of "VAM COMPONENTS" products, a passkey is required.

Please Contact us

- Movie

-

Durability in any shape - VBN Components

Vibenite ®480:A New Type of Cemented Carbide

World's Hardest Steel - Made in Uppsala, Sweden

The fast toolmaking process - from 1 to 10,000 units!:

- Maker

- VBN Components