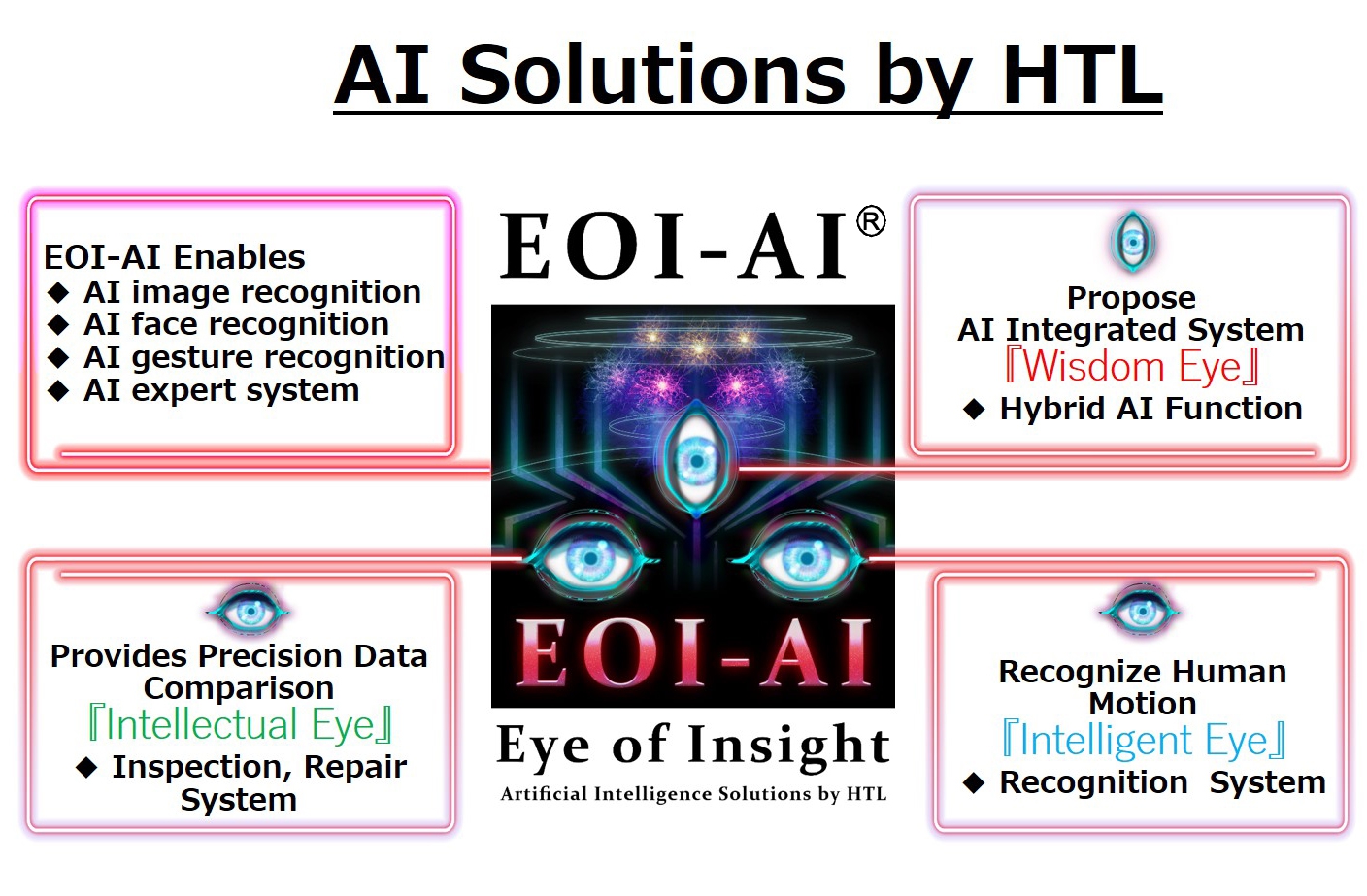

AI solution

Inspection equipment automatically detects photomask pattern defects, but if the accuracy is not sufficient, the equipment operator reviews each detected defect for confirmation.

The identified defects are corrected by the repair system. For efficient correction, the reliability of this defect information needs to be improved.

In pre-processing, mask design data and defect images are processed, and the AI engine learns the results together with defect types.

The AI engine learns the result together with the defect type.

When a new defect image is given to the AI engine, the AI engine automatically classifies defects.

We have realized this AI solution as the "EOI-AI" system.

◆ Deep Learning by Big Data of images: Defect detection, face recognition, gesture recognition are now applicable

◆ Deep Learning of expert work: Enables ease of use on advanced semiconductor manufacturing tools.

Examples:

・Recognizing hand & finger motion, touchless operation made possible on complicated machine operation.

・Maintenance & parts replacement notification will be made available based on pre-input parts life, performance data, temperature, measured values etc.

・Face recognition enables identification of individuals, gate incoming control, detection of suspicious person.

Other AI solutions are also available to support your business.

Please make use of it.

- Consultation・Estimate

-

CONTACT

※You can use our contact form or call us.