Acionity3D Products

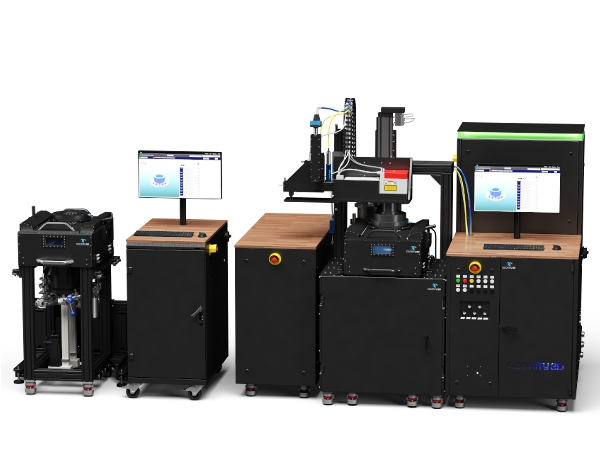

Aconity3D (Germany) laser powder bed metal 3D printer.

Additive manufacturing (AM) is performed by laying powdered metal (20 to 65㎛) on the build platform and irradiating the modeling position with a laser to repeat melting and solidification.

High-quality 3D modeling is possible even for complex shapes by importing model data that is analyzed and corrected by editing software from 3D CAD files.

Optional multi-laser (up to 4), preheating and process monitoring functions can be added as machine configuration.

Additive manufacturing (AM) is performed by laying powdered metal (20 to 65㎛) on the build platform and irradiating the modeling position with a laser to repeat melting and solidification.

High-quality 3D modeling is possible even for complex shapes by importing model data that is analyzed and corrected by editing software from 3D CAD files.

Optional multi-laser (up to 4), preheating and process monitoring functions can be added as machine configuration.

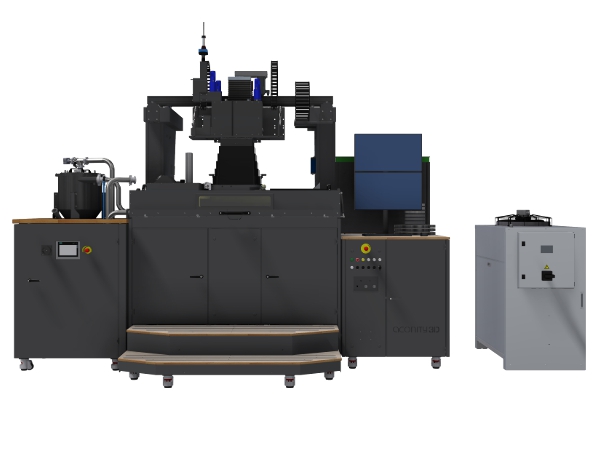

AconityTWO

AconityX

AconityMIDI

AconityMINI

- Machine Spec

(AconityTWO System) -

・Max Build Space:φ 400 mm × H 400 mm

・Fiber Laser (W) (Option):200 / 400 / 500 / 700 / 1000 / 1200

・Preheat (℃) (Option):500 / 800 / 1000 / 1200

・High-Speed CMOS Camera (Option): Process Monitoring

・Dual Pyrometer (Option): Melt Pool Emmission Measurement Function

・Procecc Parameter: Open

- Materials of Standard Process Parameter

- AlSi10Mg、Ti6Al4V、Inconel 718、CuCr1Zr、Cu-OF、Pure Titan (Gd I / Gd II)、CoCrMo、SUS316L (1.4404)、M300 Maraging Steel (1.2709)

- PDFCatalog

-

LOGIN※To view the detailed catalog of "Aconity3D" products, a passkey is required.

Please Contact us

- Movie

-

AconityTWO Metal 3D-Printing Production System

Aconity3D 4 Laser LPBF Single Parts

Aconity3D Multi-Scanner Infinity Wobble

Aconity3D Productivity Demonstrating object made from Bainidur

First Pure Copper Part Built with Aconity Machine Applying Green Laserlight

Aconity3D High Speed Process Monitoring

- Maker

- Aconity3D